Regularly scheduled maintenance saves money in the long run

How often do you review your maintenance schedule? Sounds easy to schedule service, maintenance and repair into our itinerary but how many of us actually do?

We all know equipment wears out but if it happens unexpectedly what is it costing you?

When something stops working we often go into panic mode. Who has time to manage an emergency? This can leave you feeling vulnerable or taken advantage of with costly repairs. During downtime you lose time and more often than not time = money.

Paying a premium for parts, service or the air freight charges to expedite a repair can be costly. In an emergency situation you could make a poor decision because you don’t have more time to weigh options.

When you have the opportunity to schedule maintenance tune ups you limit the emergencies. Service can be booked ahead or completed after hours to not incur downtime. Schedule cleaning, servicing and inspections to make sure things are running optimally to avoid delays or wait times. Regular servicing increases efficiency and reduces costs.

We want to respond, not react! It’s Murphy’s Law to run out of propane when you’re BBQing the perfect steak – easily avoided with a little planning. Like your BBQ propane, ultimately staying on top of potential issues can help prevent untimely and potentially expensive breakdowns.

Budget maintenance finances over the year – if your service person raises a mechanical concern you can still allow time to gather the funds or distribute higher expenses over a longer period of time.

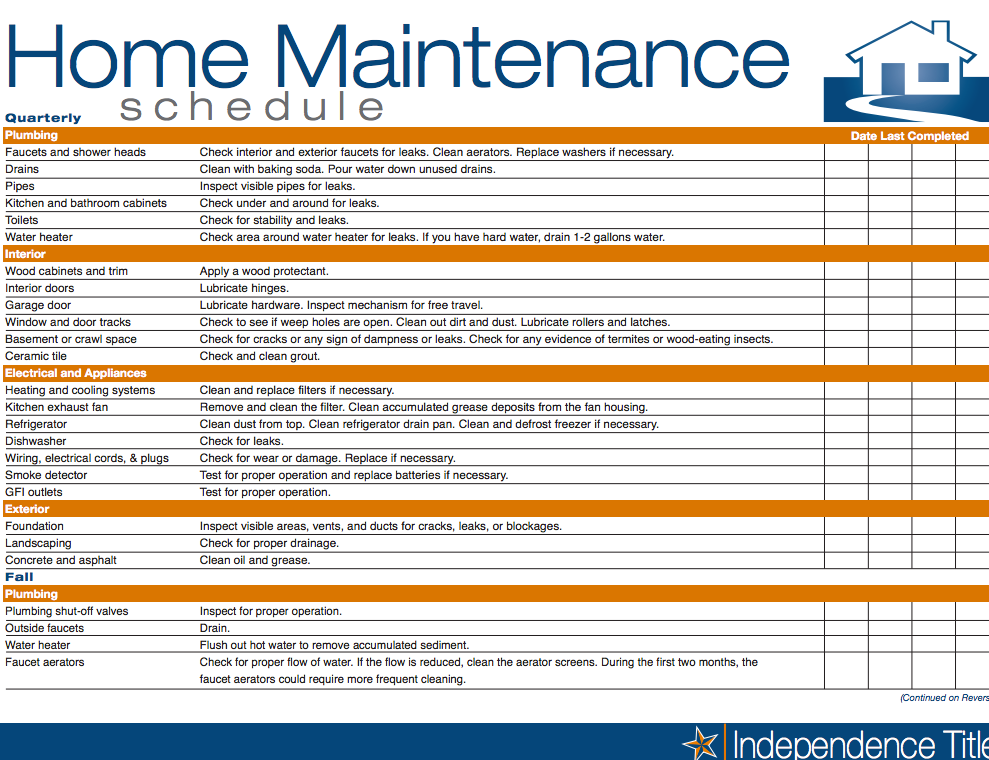

So the final piece of the puzzle. What steps do we need to take to create an effective maintenance plan?

- Take detailed inventory of your equipment. Do a walk through of your workspaces and list all of the resources you need to run your business effectively.

- Schedule the work and prioritize maintenance. When you have a detailed list of all your equipment requiring regular maintenance you need to determine when each needs to be serviced. Take into consideration the equipment with the highest return on investment and which equipment you use most often.

- Use a dating frequency, running hours or measures that will provide insight into the condition of an asset. The schedule allows you to do predictive maintenance.

- Add workers or contractors – include the estimated working hours.

- Remember spare parts. You can add stock quantities now or later as you do the work and get insight into how many pieces you need for the job.

- And lastly, don’t forget the Work Permit. Highlight if the contractors need a specific work permit.

There are software programs available with simple and intuitive solutions. Many are easy to use and will assist you to bridge all the gaps in your regular maintenance planning. In the long run, being proactive and scheduling regular preventive maintenance will go a long way in avoiding unexpected, expensive repairs.